Lyocell, The Sustainable Fabric Obtained From Wood

Lyocell has great advantages over other fabrics such as polyester and even over conventional cotton and silk. The production of lyocell is more sustainable and requires less use of chemicals.

With lyocell you can make all kinds of very attractive garments, with a soft touch, good drape and resistance to wrinkles. But the most interesting thing is that it is a more sustainable fiber than conventional cotton or viscose because it requires less use of water and other natural resources.

How is lyocell produced?

Lyocell is produced from cellulose from wood, from trees such as beech, eucalyptus, fir or pine. There are other textile fibers that come from wood, such as viscose, but lyocell has the advantage that it does not require the use of chemicals that are harmful to the environment.

Is lyocell a natural fiber?

Although it is easy to find advertisements and articles stating that lyocell is a natural fiber due to the fact that it comes from wood, the truth is that it is technically defined as an artificial fiber, because industrial chemical processes are necessary to produce it. But that it is artificial does not mean that it is less sustainable or less healthy than other really natural fibers.

Is lyocell better or worse than cotton, silk, and other fabrics?

Lyocell, currently marketed under the brands Tencel, Excel and Newcell, has been produced industrially from eucalyptus wood since the late 1980s. It is increasingly used by the textile industry for its good qualities in relation to aesthetics and sustainability.

Textile expert and professor Antonio Solé Cabanes affirms, for example, that it is more breathable than cotton (it absorbs twice as much moisture), more elastic and durable, it is biodegradable and very versatile, since all kinds of garments can be made.

Its softness against the skin and its behavior against humidity make it very suitable for making sportswear.

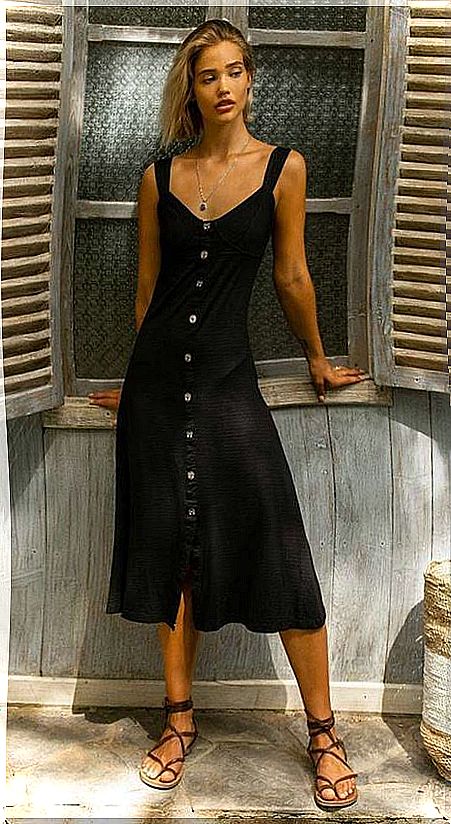

Lyocell compares to silk or linen in terms of comfort. Consequently, it is often used for light clothing such as blouses, shirts or nightwear.

In addition, garments made with lyocell cool when it is hot and warm when it is cold, a quality similar to that of wool and that allows its use in garments such as pants or jackets.

The fabric naturally regulates humidity and temperature, which does not favor bacterial growth. Therefore, it is also used for duvets or mattresses and is suitable for people with sensitive or allergic skin.

So much so that it is considered a very appropriate material for baby bedding (for the duvet or sleeping bag) because it reduces the risk of heat build-up.

On the other hand, it can be easily mixed with other fibers, such as cotton, silk or recycled polyester, it is easy to care for and can be washed normally.

Clothing with built-in sun protection

The Lenzing company, the main producer of Tencel, has developed a fiber that incorporates protection against ultraviolet radiation from the sun. It is a physical protection, not chemical, so it is safe and also is not affected by sweat, as is the case with synthetic materials with UV protection.

Lyocell is not only ideal for adults, it is particularly suitable for babies. Functional properties like heat regulation for the lyocell duvet or sleeping bag, for example, significantly reduce the risk of overheating or heat build-up in babies.

Lyocell is quite sustainable

Growing the wood from which lyocell is extracted consumes up to 15 times less water than cotton plants. Eucalyptus is the most widely used tree and its cultivation can be done without pesticides or other chemicals in areas that do not steal land from food crops for humans.

Then, to produce the fiber, chemical solvents (oxides of friends) are used, but these do not remain in the fiber or are discharged into the environment, but are almost 100% reused to repeat the process in a closed circuit. The result is a fiber so clean and biodegradable that clothing can be compostable.

The only reason lyocell still doesn’t dominate the other fibers is that it is more expensive. Currently the largest production plants are in Asia and Africa, but if it started to produce in Europe the price could drop significantly in the future.

Due to its qualities and sustainability, lyocell is already used by Spanish sustainable fashion firms such as Infinit Denim and María Malo, among many others. Mango and Zara also incorporate this fiber in some collections.